Plastic-type items are all-around us – from wrapping to toys and also vehicle elements. But ever thought about how these plastic-type material goods are produced? One of many manufacturing functions employed to generate plastic material merchandise is rotomolding, also referred to as rotational molding. In this article, we will plunge to the fundamentals of rotomolding, and check out why it’s turn out to be this type of popular way of Rotomolding developing plastic material goods.

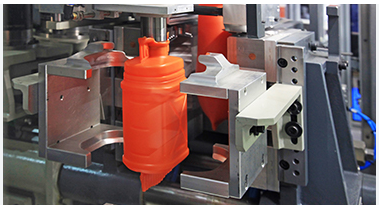

Rotomolding is actually a developing procedure that entails warming thermoplastic substance in a mildew, which happens to be then rotated on two axis to equally deliver the dissolved plastic-type throughout the mildew. After the plastic is cooled and hard, the mold is opened, along with the finished product is taken out. The process is usually useful for greater, hollow plastic-type material items that can’t easily be made using other techniques.

There are numerous advantages to using rotomolding for plastic products. One of the biggest benefits is the ability to produce huge, complicated forms. Since the dissolved plastic material is spread evenly over the fungus during rotation, the completed merchandise can be created with intricate particulars and curves that could be challenging to achieve with other molding approaches. In addition, the method can cause goods with very constant walls fullness, that can assist enhance their toughness and durability.

Rotomolding is another highly customizable procedure. The molds useful for rotomolding can easily be changed to make diverse forms or models, and therefore companies can easily alter their merchandise choices without having to put money into entirely new producing gear. Since the method can generate small or large quantities of products of any size, you can easily size down or up production in order to meet need.

An additional benefit of rotomolding is that the method is extremely effective, producing very little squander. Scrap plastic material made in the molding method can be easily reused, assisting to minimize overall waste minimizing manufacturing fees. Moreover, this process calls for little human assistance, minimizing labour fees and eradicating many prospective types of mistakes or high quality problems.

In a nutshell:

As we discussed, rotomolding can be a flexible and efficient method for making plastic-type material items. Having the ability to produce complicated designs, consistent wall structure thickness, and customizable goods, it’s no surprise this process has become quite popular in lots of market sectors. So the very next time you can see a large plastic product or service, you may value the ability of rotomolding that went into creating it.